עודכן לאחרונה 06/30/2020

Sweep Frequency Response Analysis, SFRA, is one of the most advanced electrical tests that is available for preventive maintenance, and can be utilized to detect an array of problems in transformers (both oil-filled and dry type), as well as other electrical machines such as motors and generators. It is one of the hot-topics in electrical-machinery fault analysis today.

The test is so novel, that there are still methods and standards formulated for it today. Therefore it is worthwhile to review this test, the array of faults it is capable of detecting and the standards that are available to test to today.

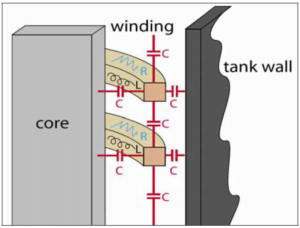

We can describe any electrical device as a distributed network of resistors, capacitors and inductors, commonly called an RLC network

Thusly, in the transformer core there are a distributed RLC network composed mainly from the capacitance between the windings and the core, the windings and the tank with the oil as a dielectric medium. There is of course inductance of the coils, distributed resistance in the coils and connectors etc.

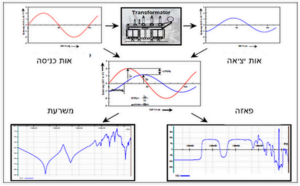

Every RLC network has a frequency response, meaning when we inject a sinusoidal (AC) voltage at a certain frequency, a response to that specific frequency is a change in the output amplitude and phase. That change depends on the specific values of the RLC network.

If we vary the response across a range of frequencies, we will get a graph that’s called the Sweep-Frequency-Response (SFR). That graph is unique to that particular RLC network and can be viewed as a ‘fingerprint’ of the RLC network. The more distributed the network, the more unique the fingerprint.

Any deviation resulting from a mechanical or electrical change in (our case) the transformer, will affect the SFR and will be manifested as a change from the fingerprint SFR. The larger the change, the larger the mechanical/electrical deviation.

An analysis of these changes in SFR is called a Sweep-Frequency-Response-Analysis – SFRA.

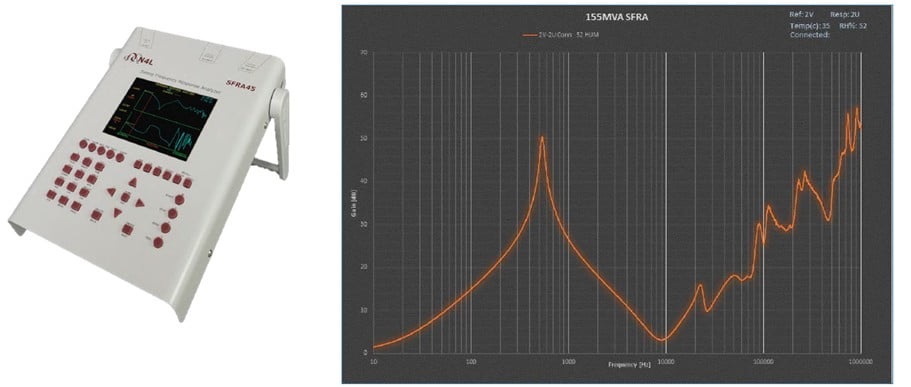

The picture below summarizes the principles behind SFRA. Mouse over to zoom.

Sweep Frequency Response Analysis – SFRA

Failures that can be analyzed using SFRA

SFRA analysis is usually based on taking a fingerprint response and checking a later SFR graph to the fingerprint. However, it is not limited to that:

- Comparison between transformers: if the transformers are identical (from same type and model) and a previous SFRA is not available, but one of the transformers is known good – a comparison between the two can help in troubleshooting.

- Comparison across time and geographies: Before transformers are shipped, an SFR is taken. At the other end of the shipping route another SFR is taken and the two compared to reveal damage due to mechanical shifts inside the transformer during shipping.

Types of faults detectable by SFRA:

Mechanical faults:

- Telescopic (up/down) movement of the coils due to electromechanical forces.

- Hoop Bucking (outside/inside) as a result of coil collapsing

- Entire phase mechanical shifs

- Angular shifts of the conductors and coils (usually low voltage phases)

Electrical faults:

- Shorts between the coils

- Shorts between coil and core (laminations)

- Disconnects in the coils (phase disconnected)

Core faults:

- Shorts in laminations creating turbulent eddy currents resulting in rising losses

- Loose laminations

Connector faults:

- .Loose connections in conductors/tap changer

- Loose internal earthing connectors

Insulation faults:

- weakened insulation (both oil and resin)

- shorts/discharge inside insulation.

Instruments for SFRA must be very precise and it is usually wise to use the same instruments for the entire SFRA test suit.

To summarize, SFRA is an advanced tool in the arsenal of troubleshooting problems in transformers and other electrical machines.